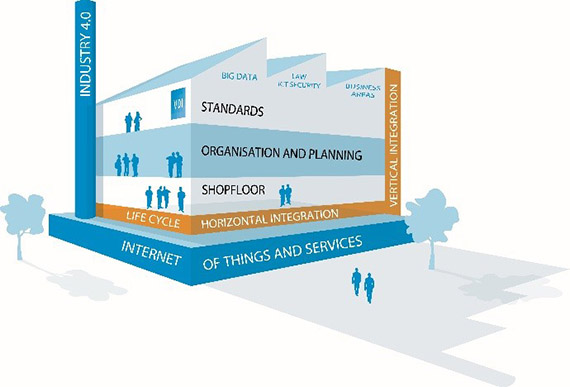

For implementation of Industry 4.0 two things are necessary:

- A machine monitoring device that monitors the data from the machine and stores that data in a common database.

- Software that displays the data stored in the database in an efficient manner.

For start using ERP first you need a machine monitoring device that collects the data from the machine and stores the data in the database once this is done you can use that data in any Industry 4.0 applications.

Industry 4.0 involves two different components, the first component involves hardware sensors and cloud computing, the second component involves software for running the company’s different departments: sales, finance, HR, manufacturing etc. The implementation of Industry 4.0 is done in multiple phases, and as you implement each phase you learn from your mistakes at each phase which fine tune the system at each phase.

The first three phases i.e. 1,2 and 3 involves installing the machine monitoring device that provides data to the software. In phase 2 and 3 involves production and productivity monitoring. After implementing these phases it monitors the data 24/7 and sends the data to the database. The last phase is to improve the functionality of the existing ERP or other software and helps to interact with the database.

G.A.POSM enables the software to easily collude with the database of the machine monitoring system. It also enables Industry 4.0 to expand the industry at your own pace. Industry 4.0 helps to automize and monitor the processes in a manufacturing industry. Once you implement Industry 4.0 in the industry you are sorted and you can sit and relax.

Advantages of Industry 4.0 are as follows:-

- Industry 4.0 helps the devices to communicate with each each other with the interference of any third person.

- One can monitor the working of the machine in real time and from anywhere and anytime.

- IOT helps to monitor the downtime, breakdown time, run time, stoppages, number of items made on the machine, etc.

- All the data is stored in database and monitored by a machine monitoring device which helps you to access the real time data and duplicacy is avoided, there is maximum utilization of resources, manpower and time.

- Industry 4.0 is one of the change in industry that helps to automize all the operations in the industry.